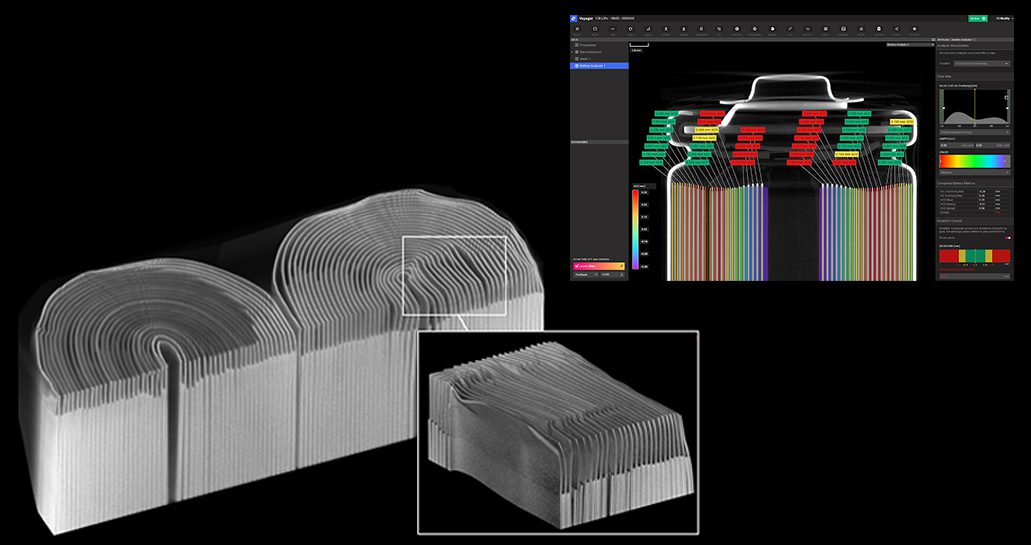

Traditional battery testing methods often fall short in detecting internal defects or optimizing complex designs. CT scanning addresses these challenges by providing non-destructive, detailed internal visualizations of battery cells, enabling engineers to find misalignments, folds, tears, and other internal defects without disassembling the cell. This capability accelerates development, enhances reliability, and supports faster innovation cycles.

In research and development, CT scanning is invaluable for accelerating material development by visualizing the distribution of materials within a battery cell, allowing for the early detection of flaws like internal cracking or voids. It also aids in identifying defects in new chemistries and form factors, such as delamination in solid-state batteries or dendrite formation in lithium-metal systems, which are critical for ensuring performance and safety before large-scale production. By integrating CT scanning into both R&D and production processes, battery manufacturers can enhance quality control, reduce waste, and bring innovative products to market more efficiently. Download this whitepaper to learn more.

Trending Products

Tow Hook Plate Mount for Rivian R1T and R1S (Gen 1 Only 2022-2024)

FREEMOTOR802® Backrest Mat Seat Back Cover, Compatible with 2022-2024 Rivian R1S, All Weather Rear Row Seat Backrest Protector Cargo Trunk Liner Interior Accessories, Black TPE 2-Pieces